I. Technological Advantages

1. High-Pressure Chamber Scroll Design Both compressors feature a high-pressure chamber scroll structure, with the motor positioned in the high-pressure zone. Compared to traditional low-pressure chamber designs, this offers significant advantages: a smoother compression process, improved volumetric efficiency, enhanced motor cooling, and a more compact, reliable structure. This design results in a higher COP value than traditional fixed-speed scroll compressors, delivering remarkable energy-saving effects. 2. Asymmetric Scroll Technology Hitachi’s exclusive asymmetric scroll structure, compared to traditional symmetric technology, features three key characteristics: less leakage and higher efficiency, lower vibration and noise due to reduced pressure difference between adjacent chambers, and prevention of over-compression, extending service life. To accommodate the high-pressure characteristics of R410A refrigerant, the bearing structure has been specially reinforced, further enhancing compressor efficiency and reliability.

3. Internal Oil Separation Technology In 2003, Hitachi first launched a new high-pressure chamber scroll compressor with integrated oil separation. Utilizing a dynamic oil balancing pipe design, it automatically regulates oil flow during parallel operation of multiple units, achieving dynamic oil level balance. This reduces the risk of dry friction caused by uneven oil return and improves overall system operational safety. II. Performance Advantages

1. High Efficiency and Energy Saving

COP of up to 4.53: Achieves industry-leading levels under rated cooling/heating conditions. Precise temperature control of ±0.5°C is realized through stepless inverter technology, avoiding energy waste from temperature fluctuations.

Full DC Inverter Technology: Compressor operating speed can be continuously and freely adjusted, automatically matching the output to the actual air conditioning load with higher precision.

Enhanced Vapor Injection (EVI) Technology: Employs a quasi-two-stage compression technology with an economizer, significantly improving EER and COP under rated cooling/heating conditions, with outstanding performance in low-temperature heating.

2. Stable and Reliable Operation

Anti-Thermal Drift Design: The CS inverter uses anti-thermal drift design to suppress harmonic currents, significantly enhancing electromagnetic interference resistance, control accuracy, and reliability.

Forced Lubrication System: A high-precision gear oil pump enables forced oil supply. This proactive lubrication method does not rely on negative pressure suction, greatly reducing startup wear risks.

Wide Operating Range: The compressor can achieve a maximum condensing temperature of 65°C, with a compression ratio extended to 14.3. It can still provide 55°C outlet water temperature at an ambient temperature of -25°C and ensure reliable operation at -30°C.

3. Low Noise and Low Vibration

Uses a hermetically sealed scroll compressor with minimal vibration and low operational noise.

Optimizes compressor structure and components to reduce friction and vibration during operation.

The outdoor unit fan motor utilizes a DC inverter motor for smooth, quiet operation.

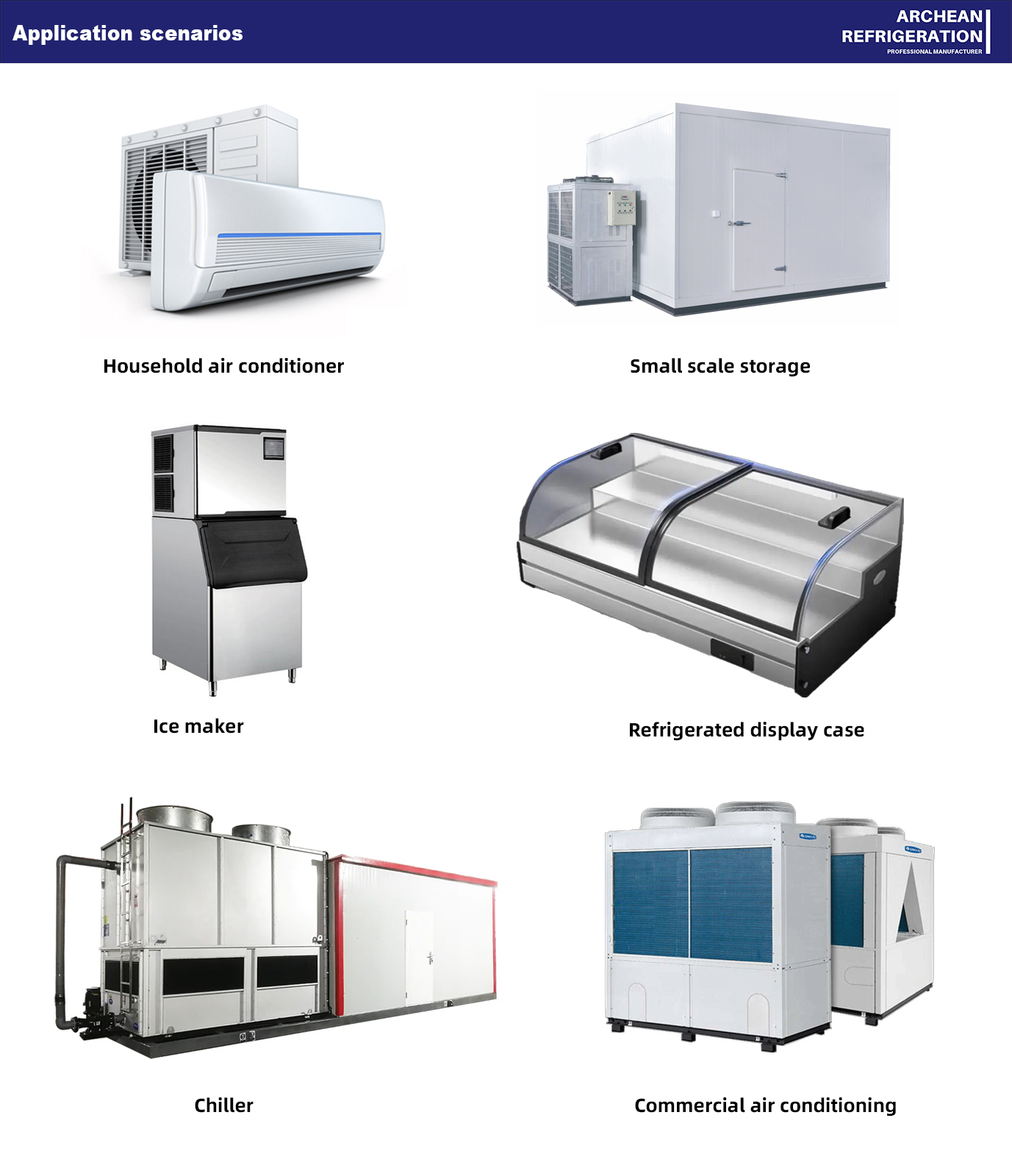

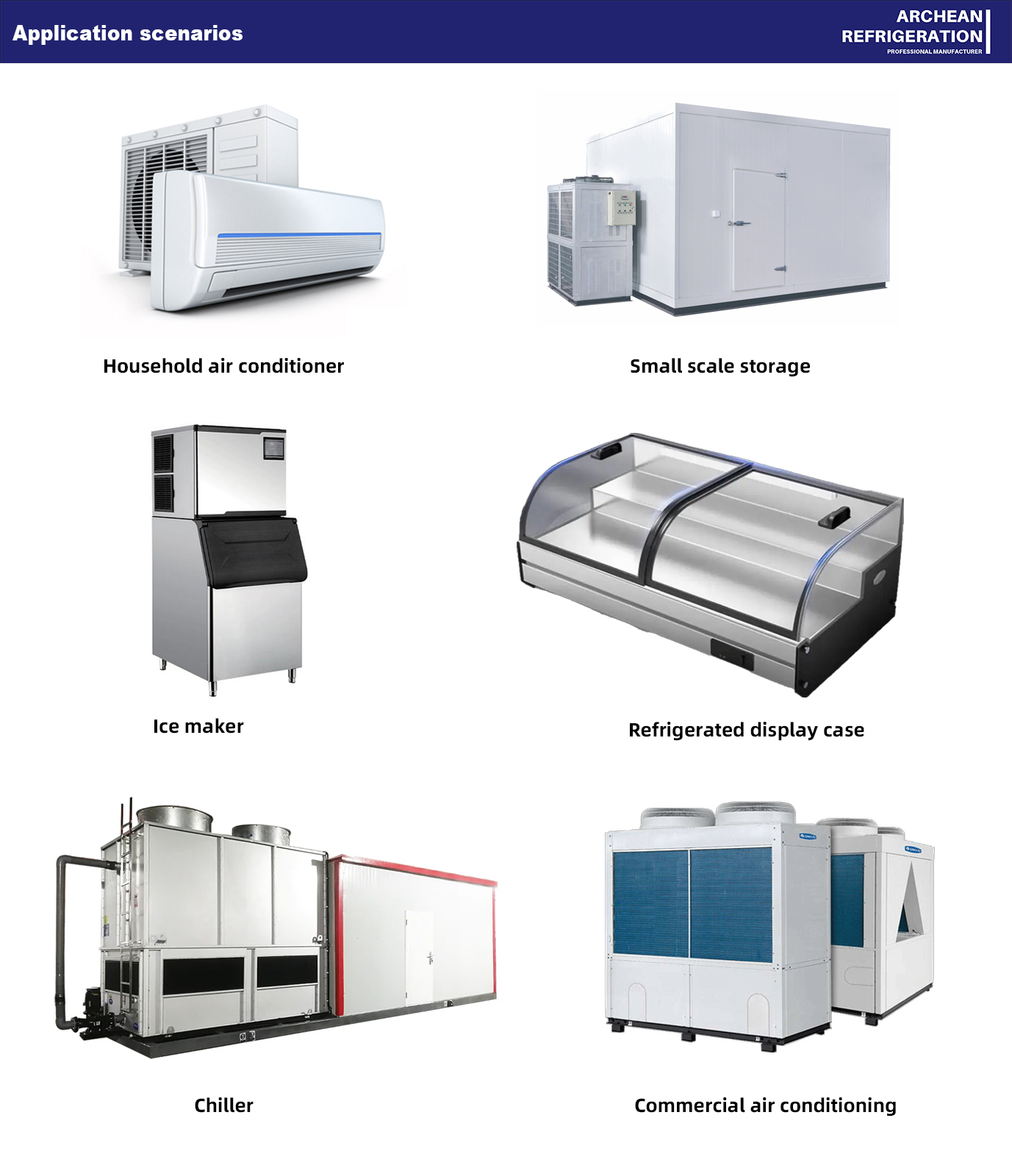

III. Application Advantages

Both compressors are suitable for various applications such as commercial air conditioning, heat pump systems, and water chillers. The cooling capacity range of 12-24 kW meets the needs of different system scales. They can also operate stably in demanding environments like data center air conditioning and precision temperature control.

Featuring a hermetically sealed scroll compressor and a fully flexible scroll design, it utilizes efficient axial + radial flexible sealing technology. This provides superior handling of liquid refrigerant or foreign matter within the scroll, ensuring efficient and stable unit operation with a service life exceeding 20 years.

Supports various intelligent control functions, such as automatic adjustment of pressure and temperature parameters, to meet personalized cooling/heating demands. The output frequency range is 0Hz-480Hz, with frequency control precision up to 0.01Hz, enabling precise control of compressor operation.  IV. Environmental Advantages

IV. Environmental Advantages

Utilizes the environmentally friendly refrigerant R410A, with an Ozone Depletion Potential (ODP) of 0, and reduces carbon emissions by approximately 30% compared to traditional refrigerants. It also supports low-GWP (Global Warming Potential) refrigerant technologies like R32, R454B, and R290, aligning with dual-carbon goals.

Summary: Leveraging core advantages like the high-pressure chamber scroll design, asymmetric scroll technology, and internal oil separation, the G503DH-80D1(2) and G503DH-83D1(2) compressors excel in energy efficiency, reliability, and quiet operation, making them ideal choices for commercial air conditioning and heat pump systems.

IV. Environmental Advantages

IV. Environmental Advantages